Materials

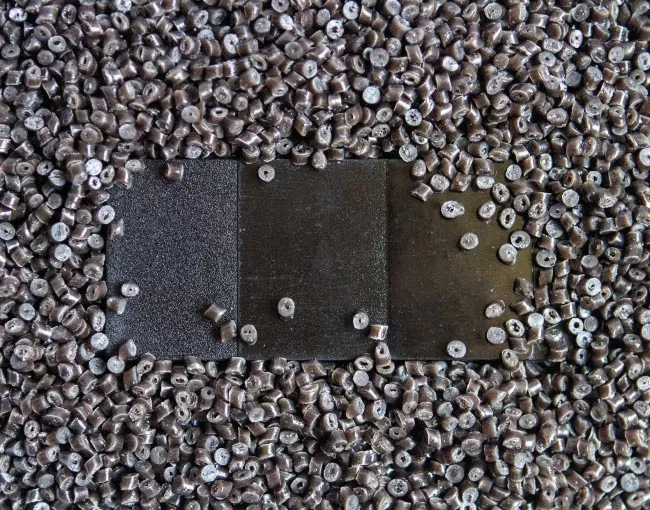

In collaboration with our research and compounding partners, we develop thermoplastic materials in which the recycled coffee grounds constitute a new input. Mainly suitable for injection molding, our pellets adapt to several application contexts, including automotive, tableware, promotional and service products. All our compounds are distributed by Nexeo Plastics.

Our innovation

The patent

In collaboration with the Department of Chemistry, Materials and Chemical Engineering “Giulio Natta” and Fondazione Politecnico di Milano, we have filed a patent application for the extraction of nanocellulose from coffee grounds and its functionalization for the creation of materials to be used in thermoplastic compoundings. This is a fundamental step towards our goal of creating new raw materials that contain at least 50% of coffee grounds.

End of waste

The circularity of coffee grounds

Coffee grounds are defined as the waste produced after roasting and consuming coffee. Among the most voluminous organic waste, it is estimated that 9 million tons of coffee grounds are produced in the world every year. During their disposal in landfills, they produce high environmental costs due to the emission of CO2 and management costs. At Coffeefrom, we reverse the course, collecting 200 tons of coffee grounds per year from the food industry as a by-product to create new production inputs.

Our social impact

An inclusive supply chain

We are an innovative start-up with a social purpose and we believe in a return economy, in which recycling and social impact coexist. For us, circular economy is instrumental in creating a social impact. For this reason, we have created new inclusive job opportunities for fragile workers within the storage and processing phases of coffee grounds, indispensable activities for the creation of all Coffeefrom® compounds.

Coffeefrom® Bio is our first material, consisting of coffee grounds of industrial origin (10-20% in variable composition) mixed with a biopolymer, PLA. It was born thanks to scientific research in collaboration with the Department of Chemistry “Giulio Natta” of the Politecnico di Milano and Fondazione Politecnico di Milano.

Thanks to its renewable and organic nature, Coffeefrom® Bio is 100% biodegradable, suitable for injection molding and 3D printing in multiple application fields. These include packaging, automotive, tableware and service products.

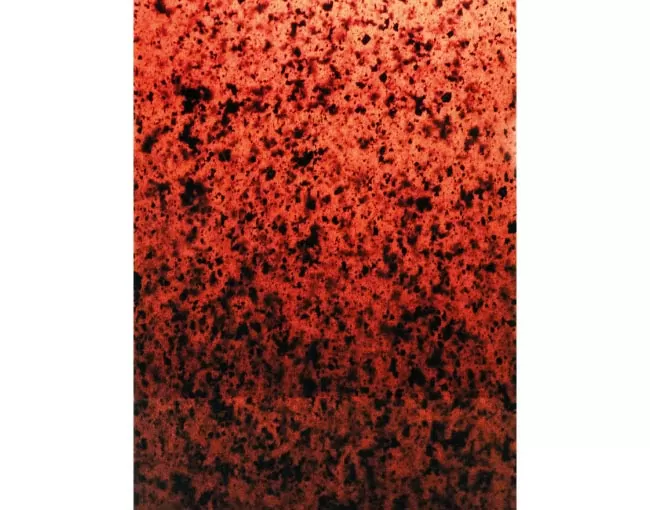

On the final injection molded products, Coffeefrom® Bio shows the natural imperfections of coffee. The material, born with its own history, already has a “tanned” color and a grit always slightly different. The softening temperature (VICAT) is 59° degrees.

Coffeefrom® Bio is available in two versions:

- Coffeefrom®-A2 (10% coffee grounds)

- Coffeefrom®-A4 (20% coffee grounds)

Coffeefrom® Eco is composed of coffee grounds of industrial origin (10%) mixed with a low-density polyethylene (LDPE) obtained from a post-industrial recycling process. A 100% recycled material, flexible and lightweight, suitable for injection molding.

On the final products, Coffeefrom® Eco enhances the natural imperfections of coffee and gives a translucent effect, ideal for playing with transparencies. The softening temperature (VICAT) is 85.3 C.

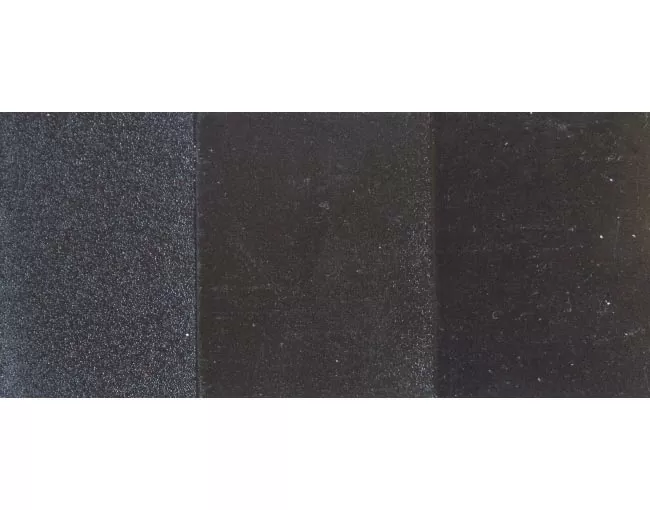

Coffeefrom® Strong is composed of coffee grounds of industrial origin (10%) mixed with a high density polyethylene (HDPE). Ideal for applications that require higher mechanical properties, Coffeefrom® Strong is a rigid material, suitable for injection molding.

On the final products, Coffeefrom® Strong enhances the dark color of the coffee wastes, with a grainy and compact effect. The softening temperature (VICAT) is 123° degrees.