What is the right bioplastic for packaging?

As the global push towards sustainability intensifies, bioplastic for packaging is becoming a compelling alternative in the industry. Derived from renewable resources, these materials offer the potential to reduce both the environmental impact of traditional plastics and our dependence on fossil fuels. This article explores the various types of bioplastic for packaging, their applications, and the key factors to consider when selecting the right bioplastic for different packaging needs. From bio-sourced polymers that mimic traditional plastic structures to innovative compounds like the ones offered by Coffeefrom® that utilize recycled coffee grounds, we’ll delve into how these materials are shaping the future of packaging.

Table of Contents

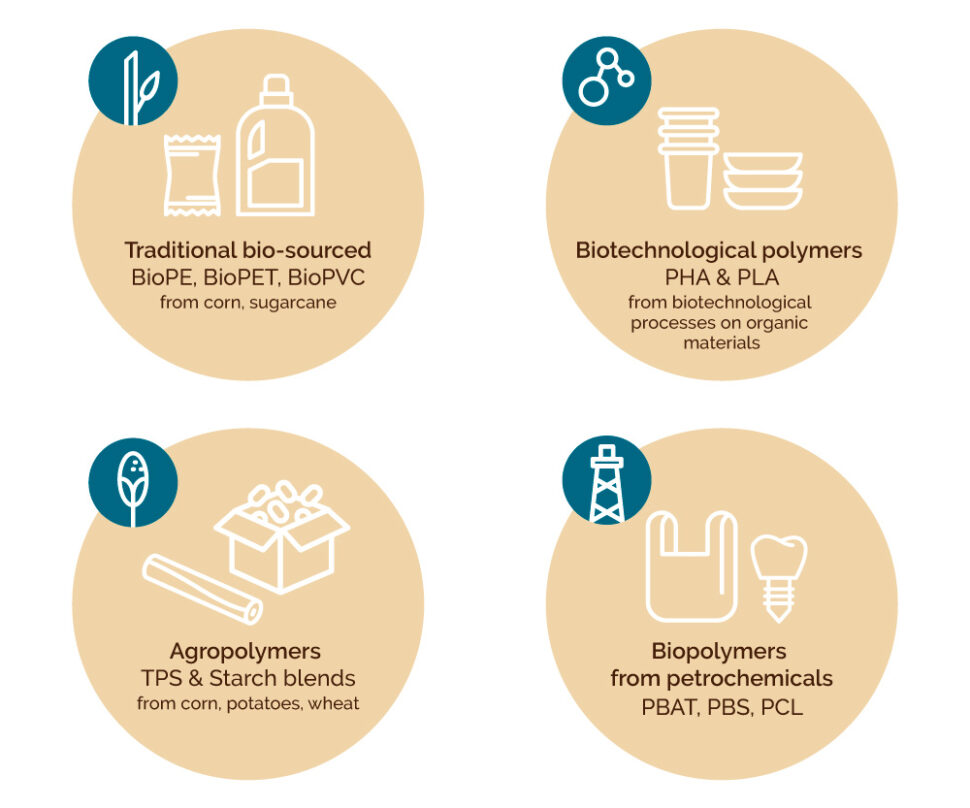

BioPE, BioPET, BioPVC; potential of bio-sourced polymers with traditional structure

Among the various types of bioplastics, BioPE (Bio-based Polyethylene), BioPET (Bio-based Polyethylene Terephthalate), and BioPVC (Bio-based Polyvinyl Chloride) represent a fascinating group because they mirror the molecular structure of their petroleum-based counterparts. This similarity means that BioPE, BioPET, and BioPVC can be integrated into existing plastic manufacturing and recycling infrastructures with minimal adjustments, offering a seamless transition towards more sustainable packaging solutions. These bio-sourced polymers are not only derived from renewable resources but also maintain the advantageous properties of traditional plastics, such as:

- Durability: offering the same strength and longevity as their fossil-fuel-derived equivalents.

- Clarity: maintaining a clear appearance, which is essential for consumer visibility and marketing.

- Flexibility: adaptable to various packaging formats, from bottles to flexible film.

- Recyclability: compatible with existing recycling streams, which facilitates easier end-of-life processing.

The image below compares the key properties and applications of BioPE, BioPET, and BioPVC:

Agropolymers: TPS & Starch blends

Thermoplastic Starch (TPS) is a standout agro polymer, gaining traction in the packaging industry for its biodegradable nature and use of renewable resources such as corn, potatoes, and wheat. This alternative to traditional plastics is making significant strides by reducing the carbon footprint associated with packaging materials.

TPS is often enhanced by blending it with polymers like Polylactic Acid (PLA) and Polybutylene Adipate Terephthalate (PBAT), which improve its barrier functions and mechanical strength. These enhancements make TPS suitable for various commercial packaging applications:

- Loose-fill packaging: TPS is used for biodegradable packing peanuts, providing cushioning for products during shipping.

- Agricultural films: applied in farming to increase crop yield and reduce plastic waste, as these films biodegrade naturally.

- Food packaging: ideal for films and containers, TPS blends offer protection against contaminants while supporting sustainability.

PHA & PLA: biotechnological polymers in packaging

Polyhydroxyalkanoates (PHA) and Polylactic Acid (PLA) are two innovative biopolymers developed through biotechnological processes, utilizing microbial fermentation of organic materials like sugars. PHA and PLA are gaining prominence for their biodegradability and reduced carbon footprint.

Both polymers are becoming integral to eco-conscious packaging solutions:

- PHA: this polymer is fully biodegradable and adapts well to applications requiring flexibility and strength, such as in packaging films, compostable bags, and wrappers. Its ability to degrade in marine environments also makes it valuable for reducing ocean plastic pollution.

- PLA: Known for its clarity and stiffness, PLA is commonly used in the packaging of perishable goods, such as fruits and vegetables, and in disposable products like cups and cutlery. It provides a viable alternative to traditional plastics with the advantage of compostability under industrial conditions.

PBAT, PBS, PCL: biopolymers from petrochemicals

Although derived from petrochemical sources, biopolymers such as Polybutylene Adipate Terephthalate (PBAT), Polybutylene Succinate (PBS), and Polycaprolactone (PCL) are engineered to be fully biodegradable. They serve as transitional materials, providing environmental benefits while still utilizing existing petrochemical infrastructure:

- PBAT: used in compostable bags that require both strength and flexibility.

- PBS: applied in packaging that demands higher thermal resistance.

- PCL: suited for long-term applications such as biodegradable medical implants.

Controversy surrounding bioplastics in packaging

Bioplastics, often hailed as sustainable alternatives to conventional plastics, face significant controversies that challenge their environmental credentials. Key issues include the potential for increased food prices due to competition for agricultural land, limited biodegradability in natural conditions requiring specific industrial composting facilities, and a carbon footprint not entirely free from emissions due to intensive agricultural practices. Additionally, bioplastics can complicate recycling processes when mixed with traditional plastics, leading to contamination and reduced recyclability. Addressing these concerns is crucial for validating bioplastics as a truly sustainable option in the packaging industry, emphasizing the need for comprehensive life cycle assessments and improved waste management systems.

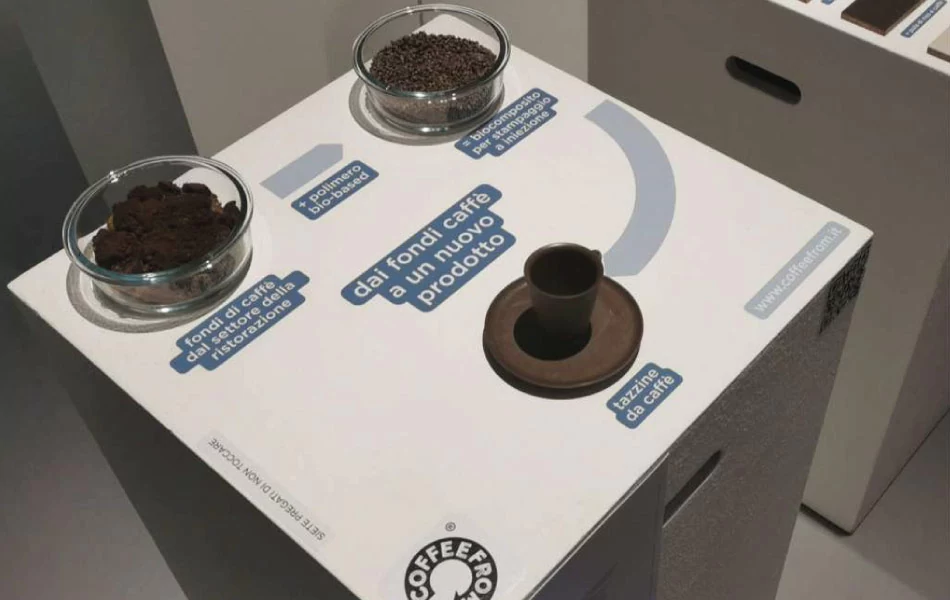

Innovative packaging solutions with Coffeefrom® materials

Bioplastics, often hailed as sustainable alternatives to conventional plastics, face significant controversies that challenge their environmental credentials. Key issues include the potential for increased food prices due to competition for agricultural land, limited biodegradability in natural conditions requiring specific industrial composting facilities, and a carbon footprint not entirely free from emissions due to intensive agricultural practices. Additionally, bioplastics can complicate recycling processes when mixed with traditional plastics, leading to contamination and reduced recyclability. Addressing these concerns is crucial for validating bioplastics as a truly sustainable option in the packaging industry, emphasizing the need for comprehensive life cycle assessments and improved waste management systems.

Conclusions

Choosing the right bioplastic for packaging involves balancing environmental benefits with practical application needs. While bio-based polymers like BioPE, BioPET, and BioPVC offer seamless integration into current manufacturing processes, biopolymers from agro and biotechnological sources push the boundaries of biodegradability and sustainability. However, the controversy surrounding the use of agricultural resources and the complexities of bioplastic recycling highlight the need for careful consideration and industry-wide standards.

By utilizing organic industrial waste, Coffeefrom materials directly tackle the problem of the competition with agricultural resources commonly attributed to bioplastic. In addition, our polymers can fully integrate within traditional recycling processes.

As we continue to innovate with materials like Coffeefrom®, it becomes clear that the future of packaging lies not just in choosing alternatives to traditional plastics, but in fundamentally rethinking our material sources and lifecycle approaches.