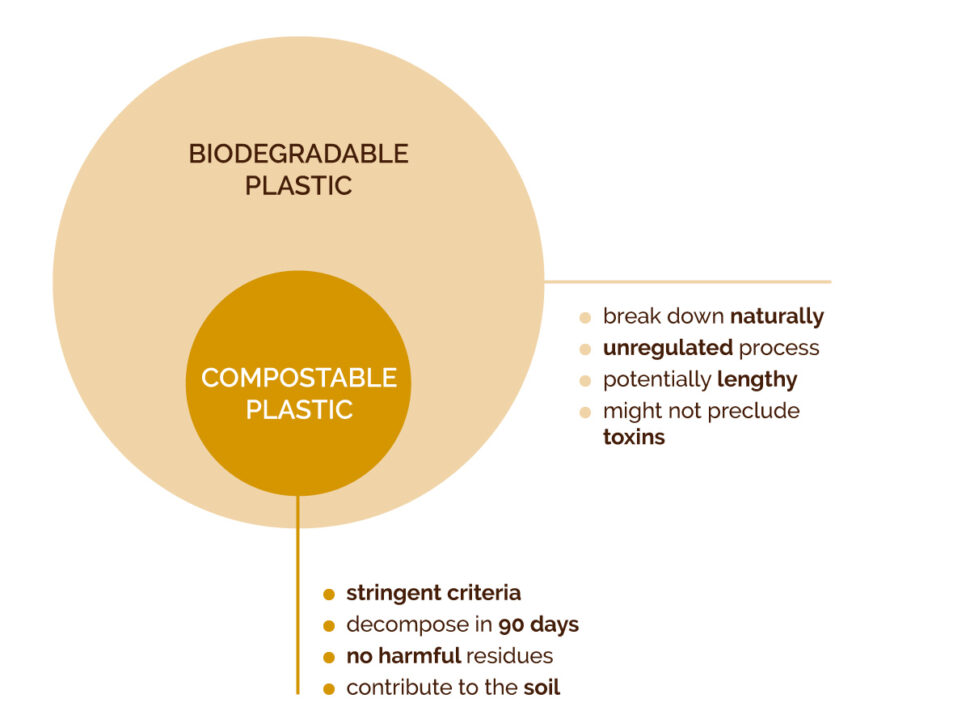

Biodegradable vs compostable bioplastic

Understanding the difference between biodegradable and compostable plastics is essential for their correct management.

Biodegradable products can break down naturally with the help of microorganisms, but the process is unregulated, potentially lengthy, and might not preclude the presence of toxins.

In contrast, compostable plastics adhere to stringent criteria under standards like the US ASTM D6400 and D6868, and the European EN 13432. These certifications ensure that compostable products decompose within 90 days in industrial composting facilities, do not produce harmful residues, and contribute positively to the soil as nutrient-rich compost.

This article delves into the factors that influence the degradation and compostability of polymers like PLA, emphasizing the importance of precise standards in their lifecycle management.

Table of Contents

Comparing biodegradable and compostable plastic

The following table provides a clear distinction between biodegradable and compostable plastic, highlighting the conditions needed for each to ensure proper disposal and environmental sustainability.

| Biodegradable plastic | Compostable plastic | |

| Definition | Breaks down naturally from microbial action. | Designed to break down in industrial composting environments. |

| Timeframe | No specific timeframe; degradation varies widely based on environmental conditions. | Must break down within a specified period, usually 90 to 180 days under controlled conditions. |

| Environmental conditions | Can degrade under a variety of natural conditions, not necessarily controlled. | Requires specific conditions such as high temperature, moisture, and aeration typically provided by industrial composting facilities. |

| End products | Decomposes into carbon dioxide, water, and biomass; may leave behind some residue depending on the environment and material. | Breaks down into carbon dioxide, water, and compost that can be used as organic fertilizer; leaves no toxic residue. |

| Standards | Fewer specific standards; biodegradability can vary widely among materials. | Must meet strict standards like ASTM D6400 or EN 13432 which include biodegradation speed, disintegration, and ecotoxicity tests. |

Key factors influencing the biodegradability and compostability of polymers

To determine whether a polymer is biodegradable or compostable, several key features and conditions must be considered. These include the material’s chemical structure, physical properties (like thickness), environmental conditions required for degradation, and compliance with specific standards. Below, we delve into these features, using polylactic acid (PLA) as a primary example:

- Chemical structure: polymers composed of natural monomers, such as the lactic acid in PLA, are more readily metabolized by microbes.

- Physical properties: the thickness of the material significantly affects decomposition rates; for instance, PLA-based products over 417 microns thick struggle to compost effectively.

- Environmental conditions: PLA requires specific conditions such as high temperatures (55°C to 60°C) and high humidity for effective industrial composting.

- Additives used: many biodegradable and compostable plastics contain additives that modify their properties, such as rate of degradation, mechanical strength, or UV resistance. The nature and amount of these additives can significantly influence the environmental breakdown process.

- Microbial environment: the specific types of microorganisms present in the environment where degradation is expected to occur play a crucial role. Some polymers may degrade well in one setting but not in another due to the presence or absence of specific microbial communities.

- Certification and labeling: to be deemed compostable, products like PLA must meet criteria like those set by EN 13432, ensuring rapid biodegradation and no toxic residue. Other certifications such as ASTM D6868 (for biodegradable plastics used in packaging) or TÜV Austria’s OK Compost label can also dictate the conditions under which a product is considered compostable.

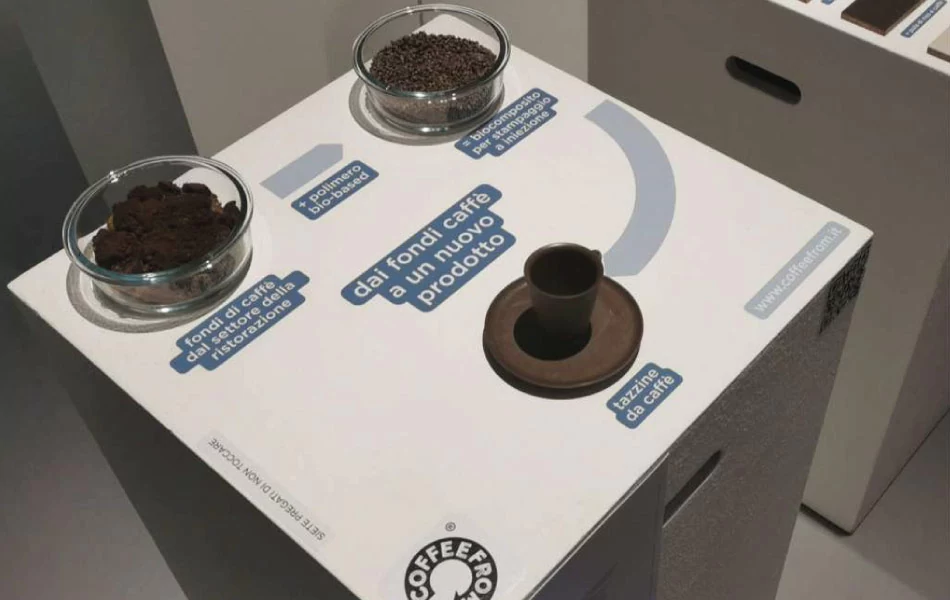

Our Coffeefrom BIO, a biopolymer blend of PLA and coffee grounds, illustrates the nuanced application of these standards. While inherently biodegradable, if printed with a thickness over 417 microns, it becomes non-compostable under typical industrial conditions.

Conclusion

Distinguishing between biodegradable and compostable plastics is vital for environmental sustainability.

Biodegradable plastics degrade under varied conditions and may leave residues, while compostable plastics, governed by strict standards like ASTM D6400 and EN 13432, decompose within defined timeframes in suitable facilities, turning into nutrient-rich compost without harmful residues.

This understanding is crucial for making informed decisions that promote sustainable material development and effective waste management.