Food Contact Materials (FCMs): an examination of plastics

Food Contact Materials (FCMs) are essential ingredients in the food processing and packaging industries. These materials, which come into direct contact with food, include everything from packaging materials to the utensils used for eating. Among the various types of FCMs, plastics are particularly prevalent due to their versatility and cost-effectiveness. This glossary explores the use of plastics as FCMs, addressing types, regulations, health implications, innovations, and future trends.

Table of Contents

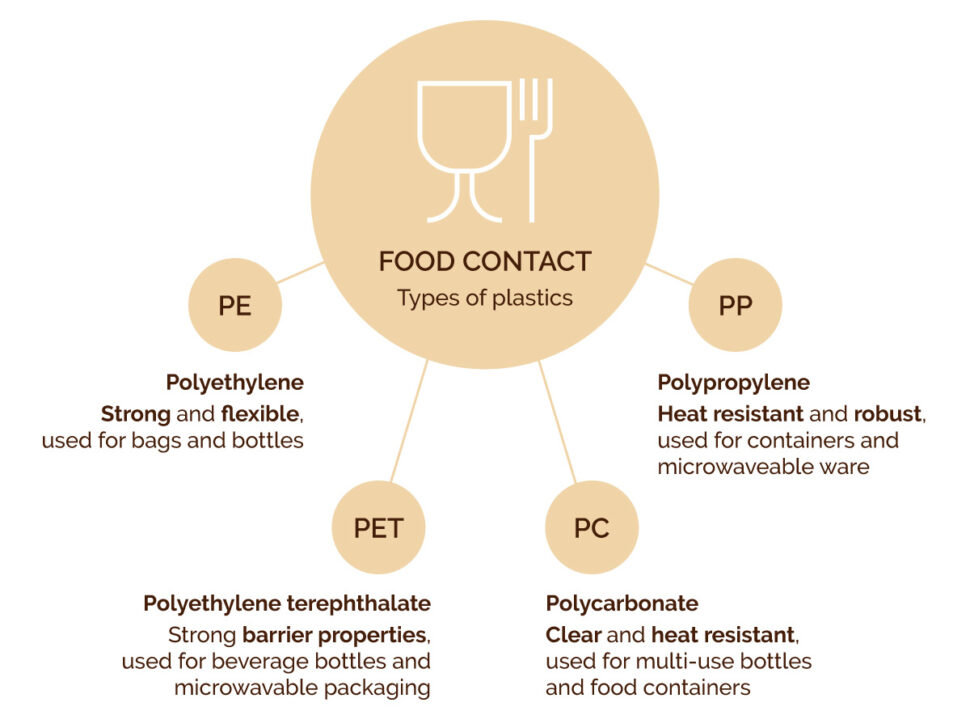

Types of plastics used as food contact materials

Plastics are favored in the food industry for their durability, lightweight, and low cost. The most commonly used plastics in food-contact applications are:

- Polyethylene (PE): known for its strength and flexibility, PE is commonly used in bags and bottles.

- Polypropylene (PP): heat resistant and robust, PP is ideal for containers and microwaveable ware.

- Polyethylene terephthalate (PET): used widely in beverage bottles and microwavable packaging due to its strong barrier properties against gas and moisture.

- Polycarbonate (PC): known for its clarity and heat resistance, used in multi-use bottles and food containers.

Many other kind of plastic, such as PLA or PHA, can be used in food contact applications and each different type offers unique properties suited for specific food contact applications.

Regulatory framework for plastic FCMs

The safety and suitability of plastics for food contact are governed by stringent regulations across the globe, ensuring public health protection:

- European Union

- Regulation (EC) No 1935/2004 sets a framework necessitating that all FCMs must not transfer their constituents to food in quantities that could endanger human health.*

- Regulation (EC) 10/2011 ensures the safety of plastic materials that come into contact with food by setting requirements for their manufacture and marketing throughout the European Union. It includes limits on substances that can migrate from plastics into food and specific labeling requirements. Its 18th amendment is expected to be adopted by the end of 2024. The amendment introduces new requirements for substances used in food contact plastics, including purity standards and rules for the use of authorized natural materials. It also clarifies labeling requirements, introduces stricter rules for waste and by-products, and updates the migration testing and analytical methods.

- United States: the FDA oversees FCMs, setting specific guidelines for plastic safety, including the conditions and temperatures at which they can safely be used.

- Asia: Diverse regulations exist, with countries like China and Japan having their own standards and safety protocols.

These regulations are crucial for maintaining the standards of FCMs and ensuring they are safe for continuous consumer use.

Health and environmental concerns

Plastics used as Food Contact Materials (FCMs) face scrutiny due to health concerns over chemical migration, such as BPA and phthalates, which can affect human health, and environmental issues related to their durability and end-of-life disposal. These challenges highlight the need for continuous improvement in both the safety standards and sustainability practices governing the use of plastics in food packaging and storage.

Innovations and developments in plastic FCMs

In response to health concerns and environmental impact, the industry has seen innovations such as BPA-free plastics and advancements in barrier technologies that minimize harmful migrations. Moreover, the development of food-contact approved bioplastics marks a significant step towards sustainability, aiming to reduce the environmental footprint of FCMs.

Case Study: Coffeefrom® Strong

Coffeefrom® Strong blends 10% industrially sourced coffee grounds with high-density polyethylene (HDPE), offering enhanced mechanical properties suitable for injection molding. Designed for applications that demand higher mechanical strength, it has been approved for food contact in the EU.

Conclusions

In conclusion, the exploration of plastics as Food Contact Materials (FCMs) reveals a complex landscape shaped by a need for durability and cost-effectiveness, balanced by health and environmental concerns. While plastics like PE, PP, PET, and PC continue to play critical roles in food safety and preservation, their use raises important questions about chemical safety and sustainability.

Regulatory frameworks in the EU, the US, and Asia play pivotal roles in ensuring these materials meet strict safety standards to protect public health. Meanwhile, developments of BPA-free plastics and alternatives like Coffeefrom® Strong underscore the industry’s shift towards more innovative solutions.