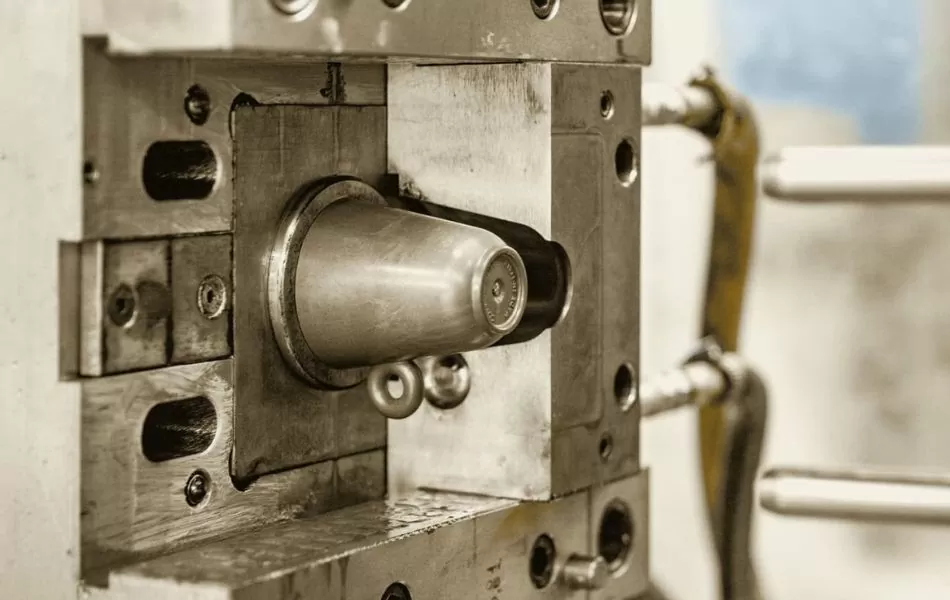

The injection molding of the Coffeefrom®-Bio material

Reduce virgin raw materials by recycling plastics at their end of life or by creating organic-based compounds. As the world of plastics evolves, so do industrial challenges, where established practice has to face new mechanical and technical features of materials. Today, we will talk about the injection molding experience of our first bio-based material, Coffeefrom® Bio.

Index |

Plastics: turning a problem into opportunity

Nowadays it is clear to everyone that we must make an additional effort to make our activities and economies increasingly sustainable. Plastics in this context represent a problem-opportunity: on one hand, the excess of packaging ending up in the environment has led to think on the impact of single use plastics; on the other hand, plastics represent a great opportunity as they are smart materials, 100% recyclable, and allow significant efficiencies and energy savings.

However, recycling is still very complex because there are more than 20 families of plastics and recycling is only possible for some of them. For an organic approach we therefore have two different strands:

- The use of second life plastics, composed of materials partially or completely recycled in a homogeneous, such as polypropylene, nylon, polystyrene or PET. In this way, it is possible up to keep up to 90% of the initial characteristics and get an interesting result in terms of life cycle assessment;

- Secondly, the use of bio-based materials, made from renewable sources and not derived from oil. They do not represent a solution for all applications, but in combination with bio-fillers they are very useful in reducing the plastic matrix and giving new characteristics.

Bio-based materials from coffee grounds: Coffeefrom®-Bio®-Bio

The PLA represents one of the most concrete application families in the new world of bio-based materials made from renewable sources. It comes from the polymerization of the polylactic acid extracted after the bacterial fermentation of bio-masses.

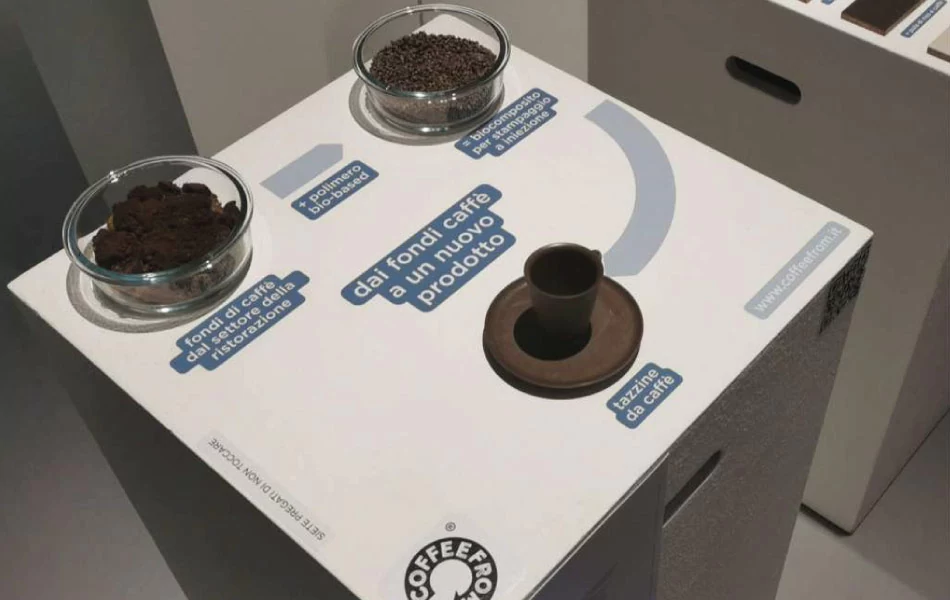

Coffeefrom®-Bio is a compound that combines bio-based polymer with coffee grounds in a variable percentage, which contributes to decrease the overall component of polymer and gives it color and natural texture. The compound can be transformed with normal injection molding systems, used for example for ABS or polycarbonate molding. However, it is important to pay attention to key aspects such as temperature management and mold extraction. The material is flexible in the most thinner thicknesses and has at the same time a significant consistency for major thicknesses. It is also warm and pleasant to the touch, with a natural aesthetic that varies from one batch to another due to its physiological variability.

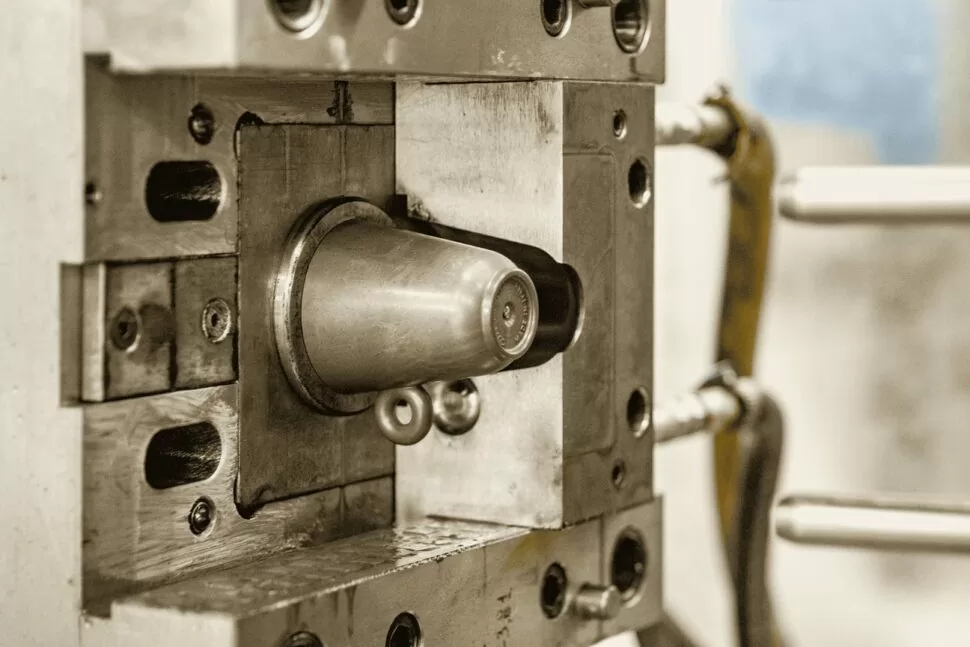

The injection molding experience of the Coffeefrom®-Bio material

Our espresso cup is the most natural and physiological application of Coffeefrom®Bio. In its realization, the geometries have been optimized also according to the mold to be created, its needs of closing lines, injection system, extraction and thermoregulation. The thickness was one of the key details to manage in order to avoid unwanted deformations. A second important detail was the combination of the needs related to the injection point. Compared to the production with very homogeneous and constant materials, the main challenge was to find the right balance between the “naturalness of the product” and the search for maximum consistency and repeatability of the result. Paradoxically, in these cases, it is necessary to maximize the control of the process and be ready for small adjustments to meet a share of physiological variability of the raw material.